It’s been almost 50 years since Bill and Jacki Shields started Form Tec Plastics in the basement of their Lake Edgewood home. Since then, the company has continued to expand its footprint and SHIELDS® Windshields has emerged as an industry leader.

Tucked away in Martinsville, Indiana, the company has developed a worldwide reputation for excellence, but how well do you know how it got there?

Second-generation family member and President, Brad Shields, sat down with his daughter, Director Alyxa McKee, who represents the third generation, and in a podcast, they talk about some of the early days of the company.

This is the first in a series of conversations hosted by Tim Surber about how the business took shape and grew over the past four and a half decades.

The early years

Brad remembers helping his dad from an early age. During the podcast, he shared a humorous story with his daughter, showing the family’s commitment to local sports and the business.

“We were still at Lake Edgewood and we had this hallway between the basement and the garage where dad started making all the molds. Mom had her office right there on the other side of the fireplace in the basement. That was the office when it started. The garage was insulated and heated so dad could work all year.

“This was probably about 1977, maybe 1976. I’m helping dad with the mold and I’m using a carving tool that he showed me how to use. We’re listening to Jerry Sichting and the boys at regionals in basketball and I ran the carving tool into my hand and had to get stitches – but we had to wait until halftime.”

Brad’s reentry into the business

“I don’t know how the conversation came up, but you know, it was tough. You know Dad had a lot of challenges and overcame a lot of obstacles so there was some tension sometimes. I told him someday I’ll take over the business. I was informed that was never, ever going to ever happen.

“I was 10.”

Despite his early declaration of taking over, his love of teaching and coaching high school football kept him occupied.

But that didn’t mean he strayed far from home.

“I worked trade shows and was always involved with what Mom and Dad were doing, but dad really wanted me to get a business degree from IU. I didn’t want to do that. I wanted to be a coach and a realtor.”

Eventually, his connection to the business continued to expand and Brad’s path ultimately lead him back home.

Working up to an office

Even after he returned, he had to work his way up to getting his own workspace.

“During the first summer, I had to build a room for our new air compressors. I spent the first part of the summer building that room and then I started working on molds. I wanted an office, but that was not happening. I finally got a desk, a stand-up desk outside my dad’s back door. No phone and a stand-up desk. I finally got a phone, but when it was raining, I couldn’t talk on the phone because of the metal roof above me. I finally asked if I could build my little office, which I did.”

Introduction to polycarbonate

The next step in Brad’s evolution was taking on polycarbonate.

“When I finally got my hands on polycarbonate, I was amazed at how much I just knew, without ever knowing I knew. I’d been touching plastic my whole life. I did work for mom and dad one summer in college and I was forming fairings in acrylic, which has some similar properties, and that taught me a lot.

“But growing up watching plastic heat and form and touching it and feeling it as a kid, messing it up, screwing it up, I really jumped into it with a lot more knowledge than I ever thought I had.”

The next generation

Brad made sure to pass that knowledge along to his children to accelerate their knowledge of the business.

“I kind of put that back to you (Alyx) and your brother a little bit. You guys played on the bags. You guys grew up doing all kinds of seat rolls. Whatever I had the boys doing, you two little monkeys would do the stuff in the background, and so when it came to athletic training, there was a lot of stuff you just did, because you’ve been doing it since you were a toddler, because you didn’t know any better, and I think that was kind of the same thing. “

As Director of Operations now, Alyx appreciated the early exposure and lessons.

“Just growing up around plastic with that all that makes sense. I’m glad and I appreciate that. When I first started, I was in the conference room. I didn’t have a place either.

The evolution of the building

Alyx often refers to the facility as a Lego building. During tours, people are usually surprised by the number of rooms that have been added over the years.

Each new building represents an expansion for the company, and it continues to this day.

You do what?

When Alyx and Brad give tours of the building, people are almost always surprised at what the company produces. As many tours as Brad has given, he’s yet to have anyone knowledgeable about the business.

“I don’t think I’ve ever had one person take the tour and go yes, that’s what I thought you did, or yes, that’s what I thought was in here. They’re like, ‘I can’t believe it’s this big’ – and it is. You need GPS or the breadcrumbs to find your way back sometimes.”

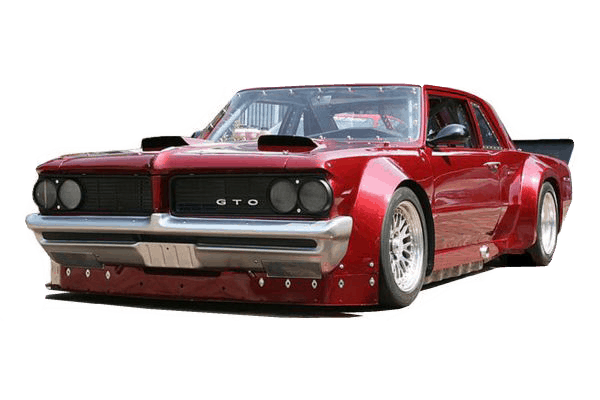

Racing to the next market

One of the contributing factors to the ongoing growth is the rapid expansion of products SHIELDS® Windshields sells. The company started out making motorcycle fairings, but with the addition of polycarbonate, it opened up new possibilities.

NASCAR, and racing in general, was the next area of opportunity. The circuit had just moved to polycarbonate from glass and demand surged as teams prepared to make the switch.

NASCAR wasn’t the only one.

“We had IndyCar using windscreens, and Riley and Scott. They used to be in Indianapolis and then after they split up, Mark’s stayed around. They would do IndyCars and so dad and Mark Scott were pretty good acquaintances, so we got into that. We were kind of on the fringe of the race car world, but we were doing custom work.”

SHIELDS® continued to build its racing presence, adding the Corvette, Camaro and Mustang molds to its lineup, followed by Ferrari’s, Jaguars and Maserati’s.

The lineup continued to expand, and the vision was to own the motorsports market.

Until heavy equipment came calling.

A cold call changes the vision

Brad envisioned eventually moving toward construction equipment, but a cold call requesting a Bobcat skid steer window changed the timing. A call to the head of engineering gave SHIELDS® its first OEM (Original Equipment Manufacturer) contract and the wheels of progress kept turning.

That was just the tip of the iceberg for the expansion of the company.

The next product was a Caterpillar skylight. It was initially hand-trimmed, but it was at that time SHIELDS® decided to invest in its first five-axis router. Once it was up and operational, Brad and two others went from 20 parts a day to 20 parts an hour.

Learning from the past

Racing was good, but construction windows were even better. The company still produces motorsports, but the vast majority of the business is dedicated to heavy equipment.

Brad sees the benefit of having done both.

“I think the way that it panned out, in order to make the construction windows the best that we do, and you can see our quality difference, is because we went through motorsports and the hard curves and the big molds.

“We had to learn to be able to do a C5 Corvette, which is a tough window. And then we could do the Dodge Viper. We had to be quick, because race car guys are like ‘Hey, I got a race in five days.’ So we learned to just jump. We became very nimble, very responsive, and very inventive. And when I say ingenuity, I’m not calling us geniuses, I’m saying we learned how to trick the system and make parts now. We really learned to form and that has put us over the top in our world.”

Alyx concurred, adding, “And that’s what we still use. We still utilize a lot of those tricks in production.”

Brad added his agreement, “It’s much more sophisticated, but the heart of us is forming. We have better heating elements, we have better equipment, we have better this and that, but we have the same tool, the same procedure and the same art.“

Moving forward

Alyx represents the third generation of Shields to work in the family business. She is tasked with expanding the vision and taking it to the next level.

That process has already begun.

“We’ve done a lot in three and a half years,” Alyx said. “I have a vision in my head of where to take this great foundation and this great product that you guys have started.”

Full podcast

To hear the full interview with all the expanded stories and anecdotes, check out our podcast on Spotify under “This is SHIELDS,” click on this link https://open.spotify.com/episode/44i2fAhvX3T0sgqbSlpVxK?si=JlKozu3kSeKodN-l8Gp1sQ or type this link in your browser. A new episode will be recorded each month.

Polycarbonate is a unique material that is 260X stronger than glass, but yet can looks so much like glass people get them confused! Being strong is awesome, but what makes it so strong? I want to quickly explain what gives polycarbonate (Lexan®) its’ strength. It’s all about being flexible!

Polycarbonate is a unique material that is 260X stronger than glass, but yet can looks so much like glass people get them confused! Being strong is awesome, but what makes it so strong? I want to quickly explain what gives polycarbonate (Lexan®) its’ strength. It’s all about being flexible!